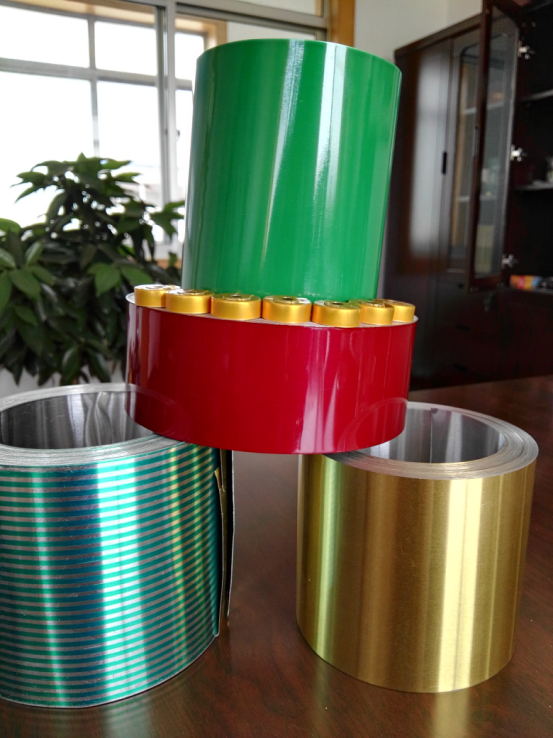

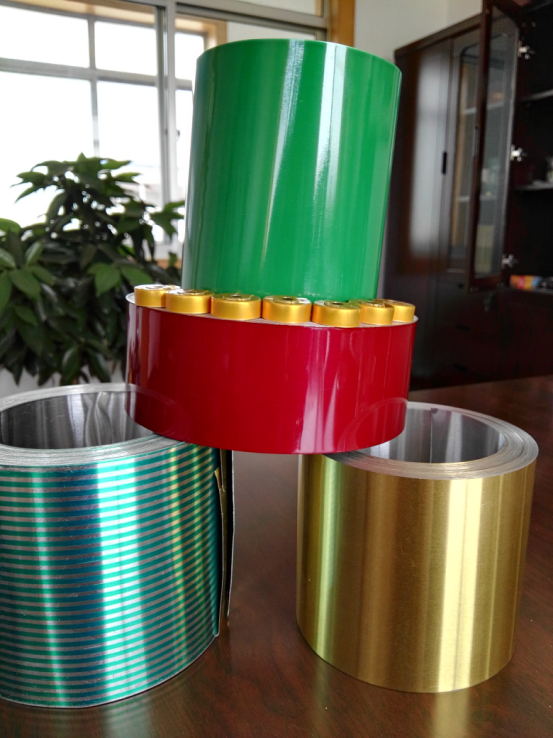

Color coated aluminum strip for crimp cap

Aluminium crimp cap normally was made by 1060, and to be anodized so as to protect its surface. However anodizing process shall cause a lot waste water, and this water pollute environment.

Nowadays aluminium crimp cap is normally use 8011 H16/H14 to make it, coated by epoxy clear varnish, or coated in different colors, normally in yellow color, golden color, red color, blue color and black color.

Color coated aluminum strip Specification:

8011 H16/H14 Thickness 0.15--0.30mm, Width: 30mm ---1000mm

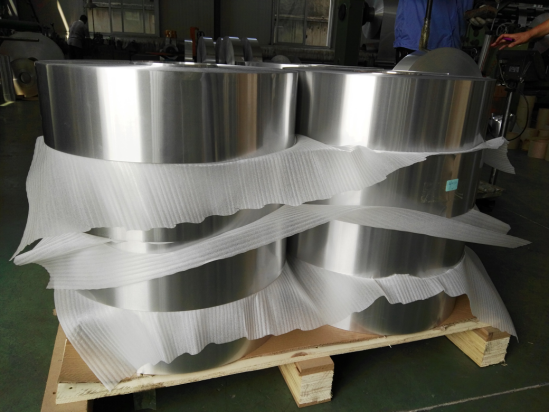

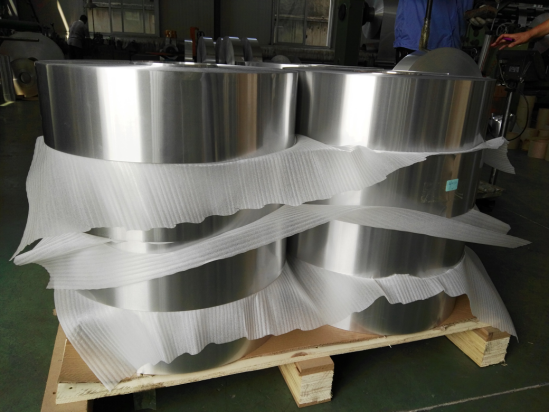

Inner diameter: Paper core 76mm, 152mm and 80mm without core.

Outer diameter: 1200mm, normally OD: 500--800mm.

Packing: Wooden case, wooden pallet if request.

Color coated aluminum strip Coating: 1. Both sides clear epoxy varnish 2. One side clear epoxy varnish, the other side color coated.

Color coated aluminum strip Coating thickness:

Golden color /yellow color: both sides coating 5-6g/m2, one side coating 2-3g/m2.

White/red/black/blue color: Both sides coating 10-13g/m2.

Color coated aluminum strip Coating quality:

1.Boiling Resistant: Boiling 121 degrees for half an hour, the paint does not fall off, do not change color.

2.Resistance to acetone and mercuric chloride: repeatedly wiping 20 times without significant stripping

Color coated aluminum strip application : pharmaceutical closures caps, aluminum crimp cap, aluminium flip off cap, aluminium tear off cap, aluminium seal cap, aluminium crimp seals, aluminum injection vials seals, aluminium seals, aluminium plastic multi caps.