- CONTACT EMAIL:

- frank@signialuminium.com

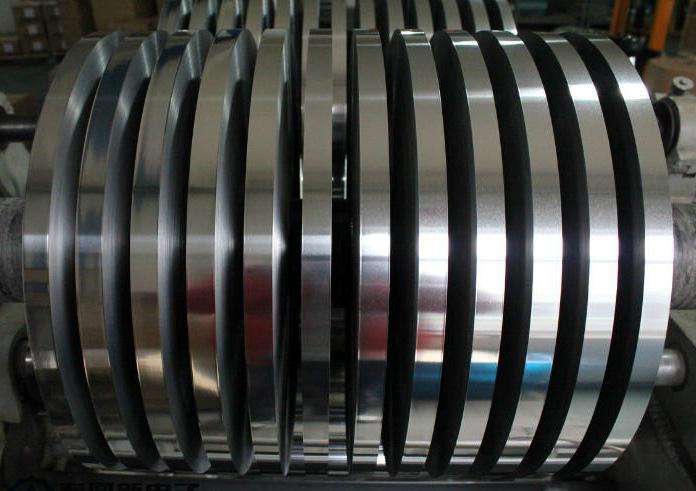

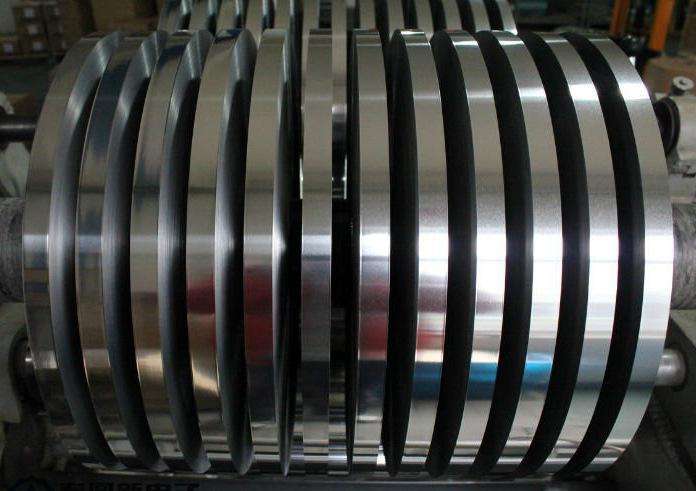

ROPP cap for small jar and bottle are mostly processed in the production line with high degree of automation, so the requirements for strength, elongation and size deviation of materials are very strict, otherwise, they will break or crease during processing. In order to ensure the easy printing of the ROPP cap for small jar and bottle after forming, it is required that the plate surface of the ROPP cap for small jar and bottle is flat, free of rolling marks, scratches and stains. Generally, 8011-h14 and 3003-h16 are used in alloy state. The specification of the material is generally 0.20mm-0.23mm in thickness and 449mm-796mm in width. The production of ROPP cap for small jar and bottle can be made by hot rolling or continuous casting and rolling respectively. At present, the production plants of anti-theft cover material in our country mostly use continuous casting and rolling stock, which is superior to casting and rolling stock.

More and more attention has been paid to wine anti-counterfeiting by manufacturers. As a part of packaging, the anti-counterfeiting function and production form of ROPP cap for small jar and bottle have been developing towards diversification and high-grade. Twist off, open, singing, speaking and multiple anti-counterfeiting ROPP cap for small jar and bottle have been widely used by manufacturers. Although the functions of anti-counterfeiting bottle caps are constantly changing, there are two main types of materials used, namely aluminum and plastic. Internationally, most of the ROPP cap for small jar and bottle are made of aluminum, which is characterized by simple shape, fine production and advanced printing technology to make them consistent in color and exquisite in design. Compared with plastic cap, ROPP cap for small jar and bottle not only has good performance, but also has low cost, no pollution and can be recycled.

The plastic anti-counterfeiting cover has complex structure and anti backflow function. Its surface treatment methods are various, with strong three-dimensional sense and unique and novel appearance, but its inherent defects can not be ignored. Because the glass bottle adopts the thermoforming technology, the size error of the bottle mouth is large, and it is difficult to achieve high sealing performance. Relevant packaging experts pointed out that due to the existence of strong static electricity, plastic caps are easy to absorb the dust in the air, and the debris generated during ultrasonic welding is difficult to be eliminated. At present, there is no complete solution to the problem of wine pollution caused by plastic debris. In addition, in order to reduce the cost, some manufacturers of plastic caps adulterate the raw materials to make them fake. The sanitary condition is worrying. Because some caps are connected with the glass bottle mouth, it is not easy to recycle. Environmental experts believe that the pollution of the caps to the natural environment is obvious. In addition, compared with ROPP cap for small jar and bottle, plastic caps cost about - times or more.

Mobile:86 17344894490

Email:frank@signialuminium.com

Address:A126 Building 4, No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan