- CONTACT EMAIL:

- frank@signialuminium.com

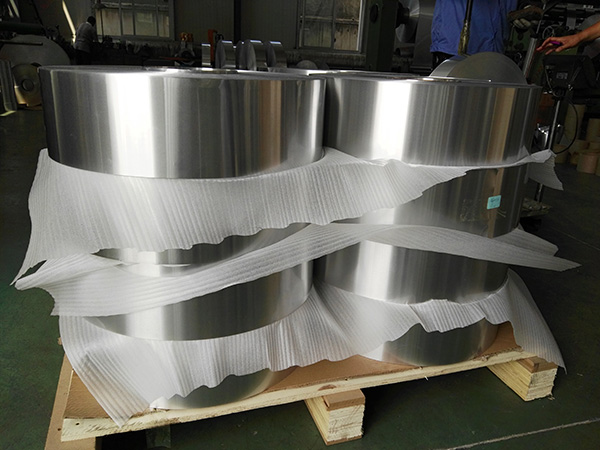

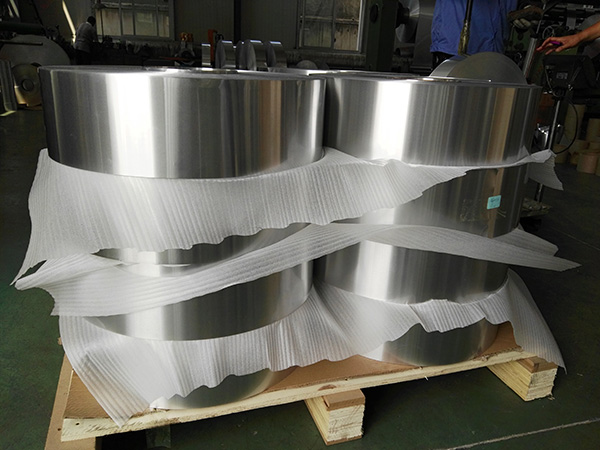

CC Aluminum Closure Sheet Foil for Omnia Cap

With the rapid development of market economy, more and more Liquor, health care companies continue to improve product quality at the same time, pay attention to the quality of the product packaging, ROPP cap is the packaging is a very effective to improve the product quality. The current domestic production of aluminum foil cap is hot rolling production, with the production of ROPP cap cast rolling stock manufacturers rarely, therefore, in-depth study of Henan signi aluminium in this area now, casting cap materials mechanical properties, such as deep drawing earing rate indicators have reached the demands of the user, the product in China, Italy, Russia, Bulgaria, etc. to realize quantities.

Production plan:

7.5mm casting rolling blank - cold rolling - homogeneous annealing in the middle thickness - cold rolling - low temperature annealing - aluminum foil rolling (60%---70% processing rate).

1. Ear rate of CC aluminum closure sheet foil for omnia cap

Earing rate is the main performance evaluation index of aluminum foil for bottle cap material. For hot rolling, homogenizing annealing treatment is an important factor but, while for the casting blank, the version of homogenizing annealing can improve the presence of anisotropic materials, but have a detrimental effect on the surface. The rolling version after a certain rate of processing stationed after homogenization annealing can also improve the stamping properties of the material. This is because in the middle of the thickness of grain product annealing is hexagonal, and in situ recrystallization, the rolling direction of the original is weakened.

Only by proper high processing rate in the rolling thickness, blank after low temperature annealing system must be appropriate, in order to obtain the recrystallization structure and rolling structure fully in the final product, cap material organization, so it is beneficial to improve the formability of cast rolling aluminum foil production cap.

The analysis shows that the deformation resistance increases and the ear is difficult to be formed after the tensile strength of aluminum foil is increased.

2. Mechanical properties of CC aluminum closure sheet foil for omnia cap

The mechanical properties of bottle cap material are mainly affected by the processing rate and heat treatment process.

3. Surface quality of CC aluminum closure sheet foil for omnia cap

There is no obvious difference between the surface material produced by cast rolling billet and hot rolled billet, and sometimes there are differences in the process of making bottle caps.

The qualified roll cap material has relatively higher tensile strength, smaller elongation and earing rate is not greater than 3%.

Conclusion:

A. The use of Casting blank, after homogenization annealing and annealing time before finished rolling again in the middle of a suitable thickness, can produce earing rate of less than 3%, three to cap material with good mechanical property, meet the requirements in the production of high-grade anti-theft cap technology.

B. Cast rolling plate directly homogenizing annealing, casting and rolling plate after cold rolling processing rate after homogenization annealing, can improve the anisotropy of casting blank, but cast rolling plate directly homogenizing annealing, easy to produce fibrous stripes in finished aluminum foil punching the cap surface. From the comprehensive index, the 8011-H16 0.2mm aluminum foil with medium thickness homogenizing annealing has stable earing effect, and has three direction properties with small difference.

C. It is easy to form fiber stripes on the side of the bottle cap produced by C. casting rolling stock. The main reason is that the three direction property of the bottle cap material is different, that is, the anisotropy is not controlled well. Only by controlling the annealing process (homogenizing annealing, intermediate annealing) and rolling pass processing rate can the strip surface of bottle cap be well solved.

Mobile:86 17344894490

Email:frank@signialuminium.com

Address:A126 Building 4, No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan