- CONTACT EMAIL:

- frank@signialuminium.com

Aluminum bottle cap has a long stretching length, so it is necessary to choose materials with better elongation. Usually, alloy 8011 alloy aluminum cap closure sheet, 3003 alloy aluminum cap closure sheet and 3004 alloy aluminum cap closure sheet are used as cap materials.

1050 aluminum cap closure sheet materials and 1060 aluminum cap closure sheet materials are also used. According to the stretching length of different products, which kind of alloy aluminium plate should be selected?

Aluminum bottle caps are usually processed on production lines with high degree of automation, so the strength, elongation and size deviation of materials are strictly required, otherwise they will break or crease during processing.

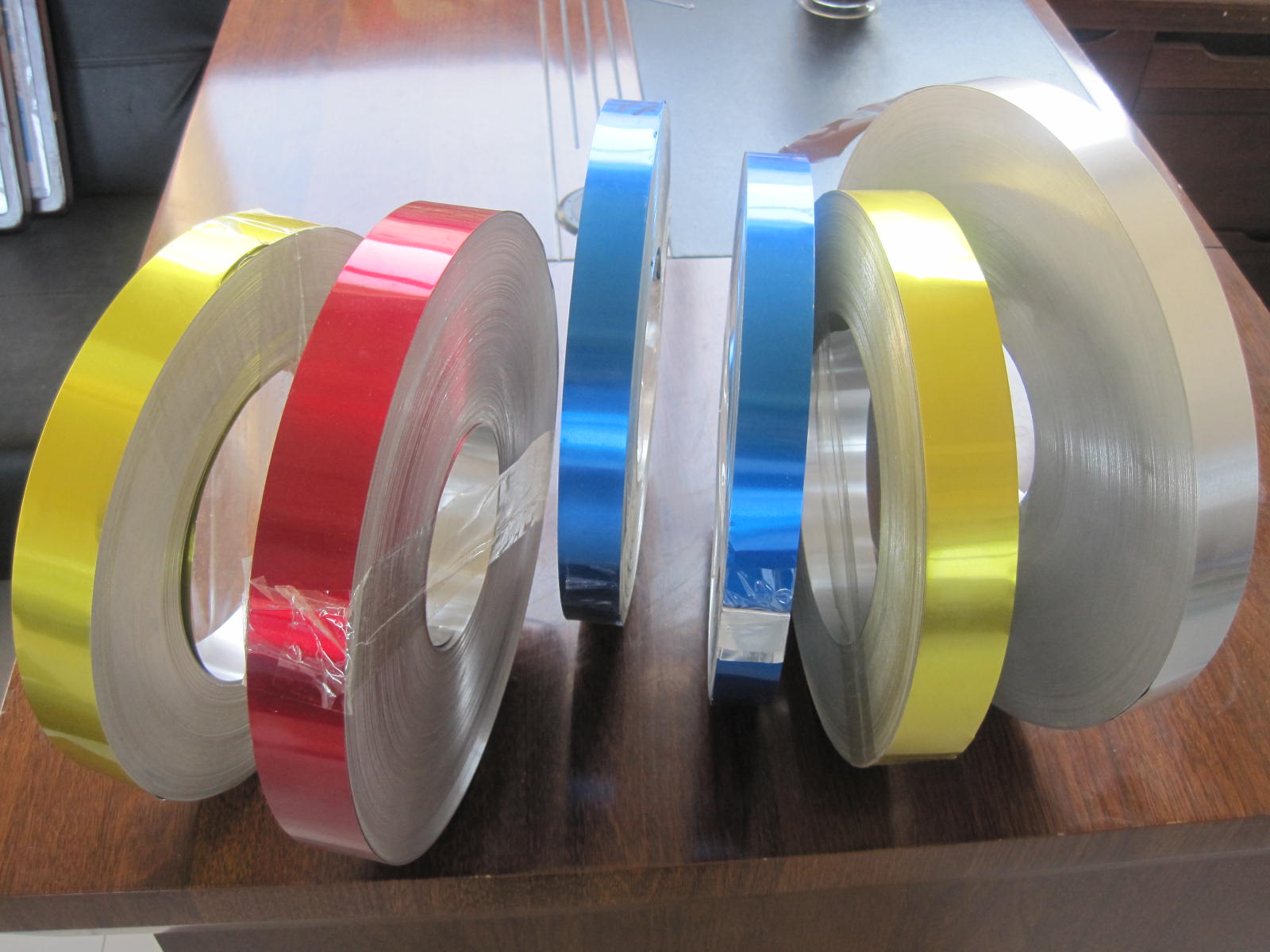

Material Requirements: Flat surface, no roll marks, scratches and stains of aluminum cap closure sheet material.

Common alloy state: 8011-H14 bottle capping material, 3003-H16 bottle capping material, etc.

Specification: General thickness is 0.20mm-0.23mm, width is 449mm-796mm.

Production mode: Aluminum bottle cap material can be produced by hot rolling or continuous casting and rolling, respectively, and then by cold rolling. At present, the multipurpose continuous casting and rolling billet is better than the casting and rolling billet in the national ROPP cap material production plant.

Mobile:86 17344894490

Email:frank@signialuminium.com

Address:A126 Building 4, No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan